Shorter response times

Recognize critical error states at a glance and initiate immediate measures to eliminate them.

All tasks in Shop Floor Management -

digitally supported with the functions of ValueStreamer®.

ValueStreamer® as a leadership tool supports the continuous improvement of processes and the optimization of collaboration.

Optimize processes in all areas of your business with digital Shop Floor Management. Learn more about the use cases.

Unrecognized deviations in KPIs, tasks and processes lead to bottlenecks, delays or quality problems. ValueStreamer® digitizes deviation management, provides a clear visualization of problems and links deviations directly to their causes - for example, to a KPI or a specific task.

Thanks to structured root cause analysis, automated action tracking and transparent collaboration, problems can be identified, prioritized and solved more quickly and sustainably. This shortens response times, reduces inefficient processes and increases the degree of added value in production.

Optimize your deviation management with ValueStreamer® - for more clarity, efficiency and sustainable improvements, because your decisions are worth more.

This is how you benefit from ValueStreamer®.

Shorter response times

Recognize critical error states at a glance and initiate immediate measures to eliminate them.

Lower costs

Reduce error rates and throughput times and avoid high costs.

Increased efficiency

Increase efficiency by automating the collection, tracking and evaluation of deviations.

Less time spent

Save valuable time in the preparation and follow-up of daily regular communication.

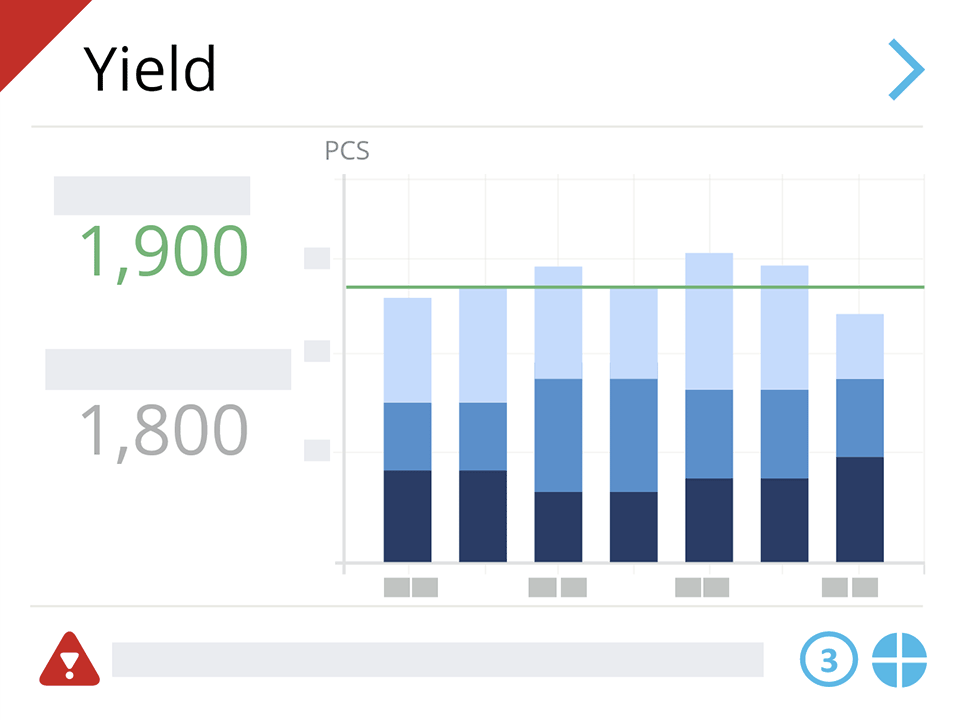

VISUAL MANAGEMENT

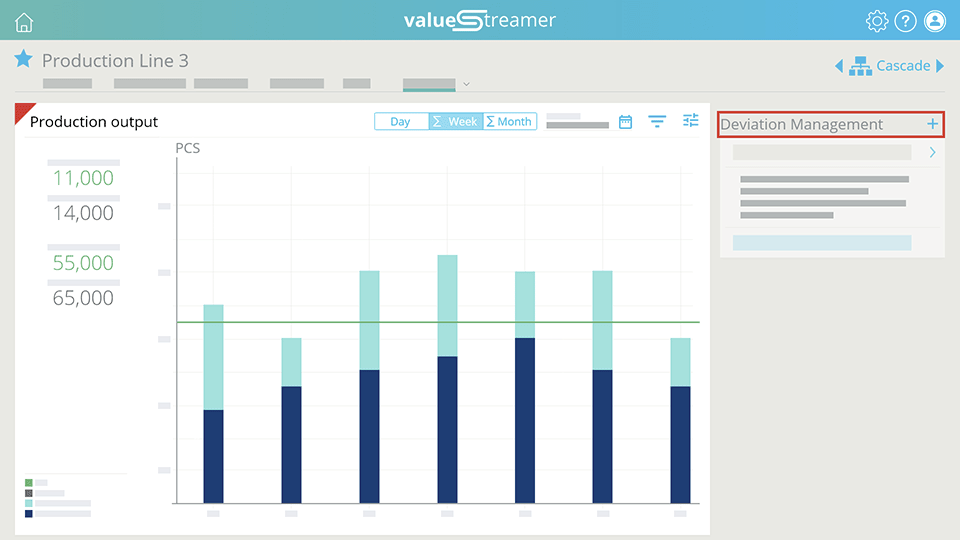

The digital shop floor dashboards from ValueStreamer® give you an overview of error states or potential bottlenecks in your area at all times - even before they occur.

Recognize deviations quickly

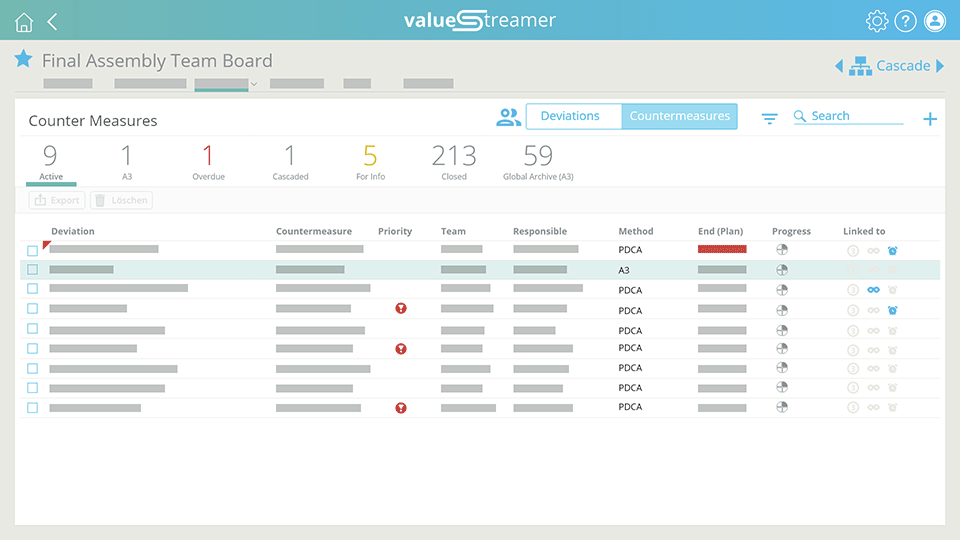

Clear visualization of deviations, individually assigned measures and tasks on the personal dashboard

Visualization of trends, reminders of deadlines, escalation when tasks are transferred

Cross-departmental, cross-divisional and cross-location management of countermeasures

FUNCTION

With the help of real-time monitoring and reporting of deviations, error states are detected at an early stage and reported automatically.

You choose whether the recording is done manually or automatically

Real-time recording of key figures, deviations or machine statuses on the shop floor via REST API interface

Linking of deviations with the KPIs and workflows involved

Upload option for important information such as images or documents and option to create notes and comments - directly on the process

FUNCTION

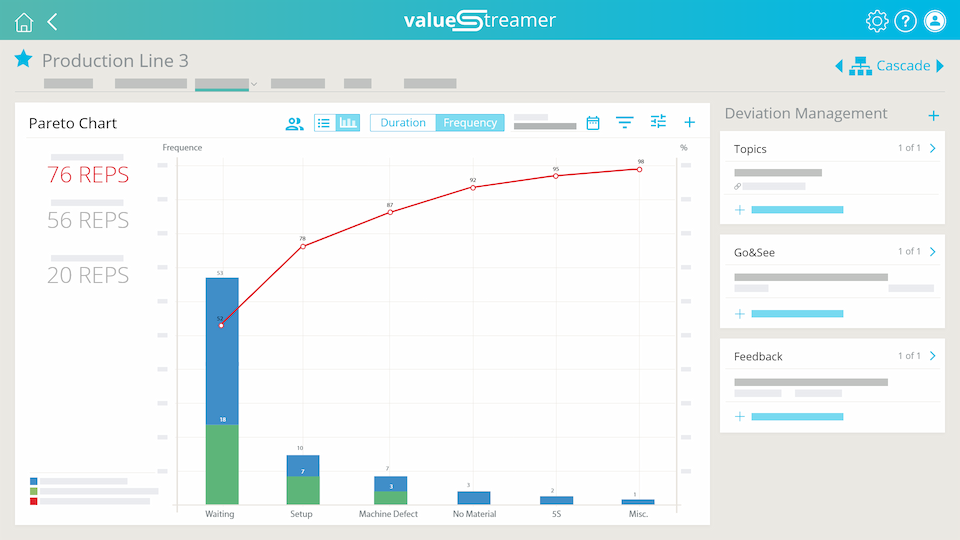

Analyze, investigate and eliminate the causes of deviations quickly and effectively by defining targeted countermeasures.

Identification of the top deviation category

Simple prioritization of deviations with automatically generated Pareto chart

Carry out the root cause analysis and initiate the structured problem-solving process - based on the PDCA or A3 method

Initiation of countermeasures, assignment of associated tasks and responsibilities for further processing within the process - directly at the deviation

Tracking progress in the elimination of deviations in the integrated action list

FUNCTION

Seamless storage of all information and documents in a global knowledge database.

Audit/ ISO-compliant

VDA-compliant

Deviation management is the process of identifying, analyzing and eliminating deviations from the target status.

In addition to recording and categorizing errors, this also includes monitoring them and defining corrections. Deviation management is an important component of quality management.

The problem solving process (PLP) is a holistic approach to analyzing and solving complex problems. Problem solving is a multi-stage, step-by-step process in which different problem-solving techniques are used in the various steps.

The problem-solving process plays a particularly important role in project management and quality management.

The A3 report, also known as the A3 method, is a form-like document template on a DIN A3 sheet and is particularly important in quality management. The A3 report is used to identify problems and develop appropriate solutions. The method is also used to plan and optimize processes. The report contains both text and graphical elements such as diagrams in order to present important information and correlations in an easily understandable way.

The A3 report covers all the steps that need to be taken to solve a problem. By using the A3 report, employees are empowered to identify, analyze and solve problems themselves.

The abbreviation PDCA stands for Plan-Do-Check-Act. The PDCA cycle (also known as the Shewhart Cycle) describes the problem-solving process in four steps: Plan - Do - Check - Act. Within the framework of the four steps, companies can continuously develop by identifying, testing, reviewing and ultimately implementing new potential and opportunities for optimization.

Find out how you can quickly identify, efficiently track and sustainably eliminate deviations:

Fill out the form and click on "Submit" - we will contact you for a non-binding, 30-minute consultation.

Further relevant advantages and functions of ValueStreamer® at a glance.

Security

User access management via single sign-on, SAML authentication, OAuth. The use of country-specific servers ensures a high level of security (ISO 27001 certification).

Web-based & hardware-independent

Easy access via the browser. With the operating systems Windows, iOS, MacOs, Android on all devices (desktop, tablet, mobile) possible.

Data integration

The API interface enables seamless integration into existing IT systems; data silos are avoided thanks to the high level of compatibility.

Simple installation

Benefit from low IT effort and costs thanks to our cloud-based SaaS solution (Software as a Service).

Traceability

Information is interlinked and integrated into the digital shopfloor workflow - creating coherent processes that are permanently traceable.

Knowledge database

Information such as measures, tasks and problem solutions are stored in a VDA-compliant manner and across locations. The result is a knowledge database that can be viewed at any time.

Find out how we doubled order throughput together with our customer WISTA.

Find out in the new study by our parent company STAUFEN.AG how companies are achieving operational excellence despite the tense situation.

Read about the areas in which operational excellence can provide significant benefits and the results you can achieve.

Find out how our customer Marquardt uses ValueStreamer® in production and benefits from digital shopfloor management.

Find out more about the advantages of digital shopfloor management in production and which functions of our ValueStreamer® software you can benefit from in this context.

Find out, among other things, how you can digitize shopfloor management in your company across the entire cascade.

Read our blog post to find out which are the 6 leadership tasks in SFM that support effective shopfloor management practice.